Full Function Engineering Exhaust Manifold Pressure (EMAP) Canister

Full Function Engineering Exhaust Manifold Pressure (EMAP) Canister

Couldn't load pickup availability

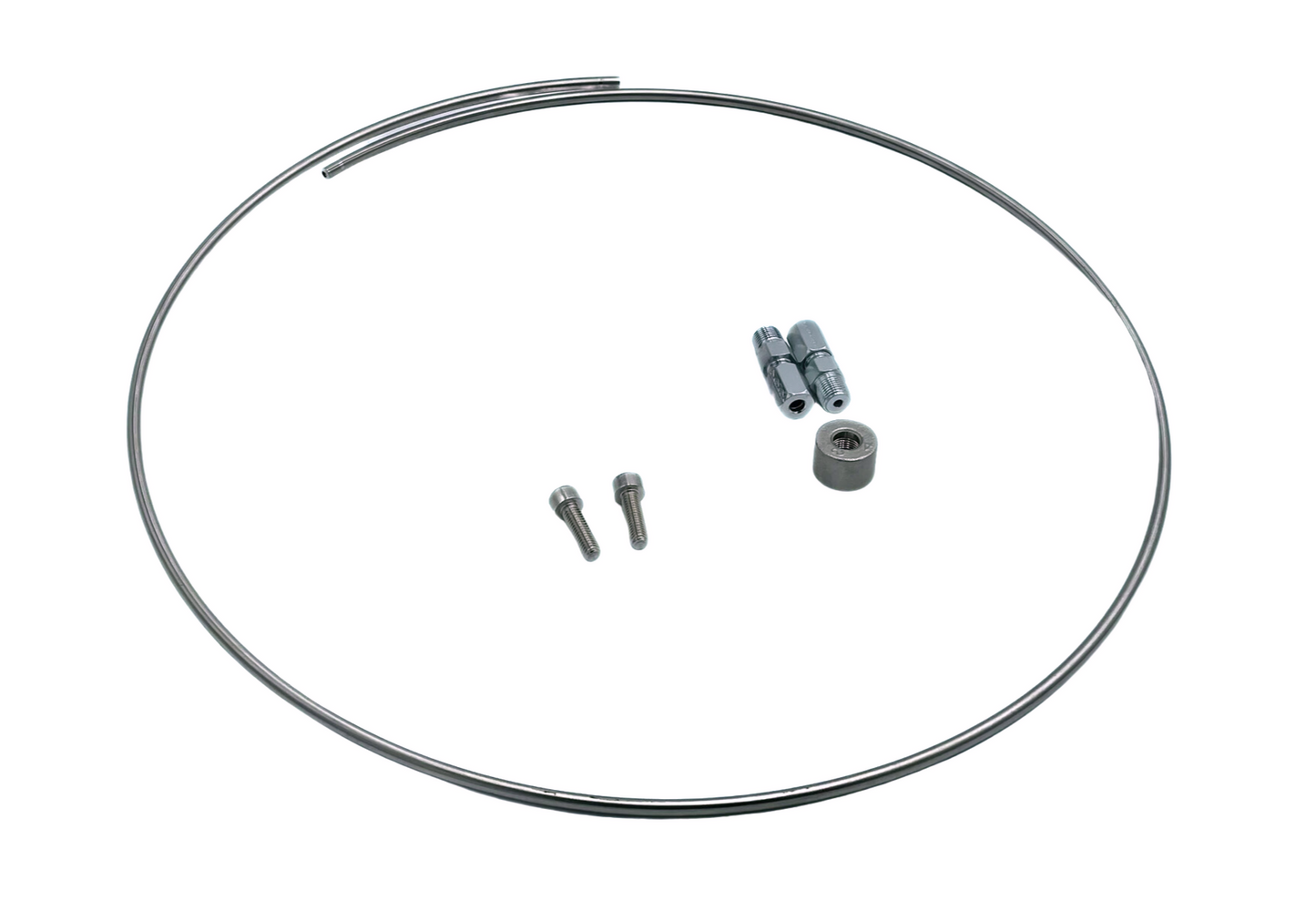

FFE EMAP (Exhaust Manifold Pressure) Canister

Running an Exhaust Manifold Pressure Sensor or EMAP sensor gives a unique insight into the dynamics of a running engine, especially one that is turbocharged.

By monitoring EMAP we can determine the following:

– Backpressure before the turbine to help size the turbo

– Efficiency of the motor (MAP/EMAP)

– If tuned for MAP/EMAP based efficiency the turbocharger can be changed without requiring a retune.

However, running a pressure sensor on the exhaust requires a few considerations to keep the sensor accurate and reliable. We need to keep heat, carbon build-up, and pressure spikes in check. Three feet or 1 meter of hardline (SS preferred) before the canister gives enough volume for the exhaust gases to cool to a reasonable temperature. Then the FFE EMAP canister’s SS wool acts as a muffler and filter to keep carbon buildup from clogging your critical sensor. In addition, our canister has a built-in pressure damper to filter out nasty pressure spikes which could kill a sensor and effect the sensor’s measurement. The body is anodized aluminum and is fully rebuildable for long life in the harsh environment.

Features:

6061-T6 anodized aluminum

18-8 stainless steel hardware

Stainless steel wool packing

Stainless sintered pressure dampening insert

Completely cleanable and rebuildable

Ends tapped for 1/8″ NPT

Share